DENKA CHLOROPRENE

Product Information

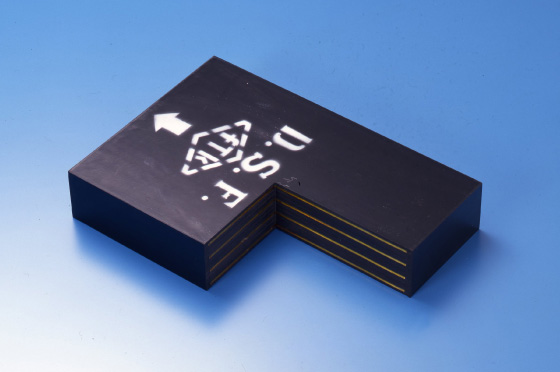

Outline

Chloroprene Rubber has many superior characteristics compared to natural and other synthetic rubbers, and is used in a variety of applications. Our company meets such needs by providing a wide range of grades such as special modified types, and latex suitable for gloves and water-based adhesives.

Characteristics

It is well balanced in physical properties, along with resistance to external environmental factors such as heat, ozone, oil, and flame.

Applications

It is used in a wide range of applications, including automotive parts, belts, hoses, electric wires and cables, coated fabrics, wet suits, adhesives, and rubber gloves.

Related Information

Comparison Between Chloroprene Rubber and Other Rubbers

Chloroprene Rubber has a good balance of excellent properties compared to natural rubber and other synthetic rubbers.

Applications of "DENKA CHLOROPRENE"

(1) Wire and Cable

It is used as the sheaths for wires and cables.

(2) Automotive Rubber Parts

Air suspensions, constant velocity joint boots, rack and pinion boots, power steering hoses, brake hoses, belts for various drives, packing, joints, dust-proof caps, anti-vibration materials are used in the requirements of automobiles.

(3) Belts and Hoses

It has a wide range of applications including conveyor belts, transmission belts, and other flat and V-belts used in mining and other fields. It is also used for various hose covers and tubes.

(4) Rubber Linings, Sponges and Wet Suits

It is used as rubber linings such as container bags, coated cloth for seats and tent curtains, leisure boats, lifeboats, and flame-retardant firefighter protective clothing. It is also used as a foam rubber or sponge with a large foam magnification for wet suits used in marine sports, as well as cushion rubbers and other items that protect human lives from the danger of flames on vehicles such as aircraft and ships.

(5) General Purposes

It is used in rubber rolls of offset printing presses which print with water and oil, rolls for steelmaking that are exposed to oil or high heat, pads and packings for various machines, and gaskets and dust-proof caps. In recent years, in addition to conventional automotive parts and general industrial rubber products, it is also expected to expand applications in civil engineering and construction fields, such as water-stop rubber and bridge rubber bearings, as well as in marine-related rubber parts.

(6) Adhesives

Among a wide variety of rubber-based adhesives, "DENKA CHLOROPRENE" based adhesives have a solid position in various fields of the easy workability and rapid bonding strength. Recently, "DENKA CHLOROPRENE LATEX" has also been well received by many clients for solvent-free adhesives.

Typical Grades of "DENKA CHLOROPRENE"

We have started the sales of "DENKA CHLOROPRENE" from four grades in October, 1962. Since then, new types have been successively added to meet the requirements of customers. The following is a list of our main grades.

*Solution Viscosity (mPa・s) : 1「5% Toluene at 20°C」, 2「10% Toluene at 20°C」, 3 ML 1+4

Elastomers Dept. Product List

- It is the customer’s responsibility to always test products before use and confirm their fitness for purpose and safety.

- Any product contained on this Website or any product using a product contained on this Website should be disposed of in accordance with laws and regulations.

- Before use, please confirm the detailed method of use, precautions, and other information by using the technical documentation and Material Safety Data Sheet. These materials are available from the relevant Division. Please request them.

- The information contained in this website is subject to change without notice as new knowledge becomes available.