CARALYAN Y/YA2 FILM

Product Information

Outline

This film uses HDPE as its base material, and is extremely easy to cut in straight lines horizontally (TD direction). We have established a technology enabling this film to be cut in straight lines by drawing it in the lateral (TD) direction. It is used in a wide range of applications where a material that cuts cleanly is required, such as foods and tape base materials.

Characteristics

- It has an excellent ability to cut cleanly in straight lines in the horizontal direction. Such ability is used by laminating with films including aluminum foil and NY, PET, OPP films.

- It erects straight up thanks to its strength in the horizontal (TD) direction.

- It is humidity and impact resistant, and has excellent tensile strength and elongation.

- Extruded lamination and dry lamination are possible.

- This film has suited the food hygiene standard of Japan.(Notification No. 370, 1959)

Uses

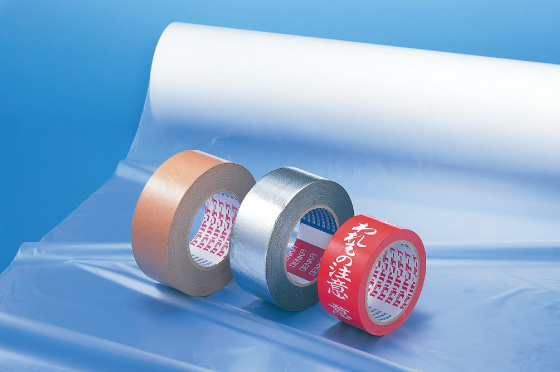

・Food packaging films, tape backing, medical wrappings films, etc..

Related Information

Uses

Technical Information

Standard specifications

Please consult with us about film widths.

Product standards and physical properties

Note: The properties above are measured values. They are not guarantees.

*1: Measured after 10 minutes of free shrinkage in Geer oven measurement temperature atmosphere

(DENKA method: Unique measurement method of DENKA based on JIS K-7128)

*2: Tear force when torn in Autograph (see JIS K-7128)

*3: Tear strength as tear force when torn in Autograph divided by film thickness (see JIS K-7128)

*4: Straightness of cut when torn at right angle in Autograph

Measurement method for ease of tearing

- Caralyan Y that has been stored in an isothermal room (23±2 ℃, 50±5% humidity) for 1 day is cut in the TD direction 50 x 150 mm, and a slit is inserted at 75 mm in the center.

- The vertical chuck of a tensile strength tester is tightened so that either 25 mm-wide side of the slit reaches 180℃.

- The edges of the film are fixed to a post with adhesive tape.

- The tear force and tear strength are calculated at each tear distance. (n = 5,200 mm/min) Note: range of 10–70 mm (10 mm intervals)

Measurement method for cut straightness

- Caralyan Y that has been stored in an isothermal room (23±2 ℃, 50±5% humidity) for 1 day is cut in the TD direction 50 x 300 mm, and a slit is inserted at 100 mm in the center.

- The vertical chuck of a tensile strength tester is tightened so that either 25 mm-wide side of the slit reaches 90℃.

- The width from the tear is measured at each tear distance. (n = 5,200 mm/min) Note: range of 50–150 mm (50 mm intervals)

Functional films

- It is the customer’s responsibility to always test products before use and confirm their fitness for purpose and safety.

- Any product contained on this Website or any product using a product contained on this Website should be disposed of in accordance with laws and regulations.

- Before use, please confirm the detailed method of use, precautions, and other information by using the technical documentation and Material Safety Data Sheet. These materials are available from the relevant Division. Please request them.

- The information contained in this website is subject to change without notice as new knowledge becomes available.