DENKA BLACK

Product Information

Outline

"DENKA BLACK" is acetylene black, a type of carbon black, obtained from thermal decomposition of acetylene. It is highly purified and extremely conductive; these characteristics make it an ideal material in the production of dry cells, electric power cables, as well as in such sectors as silicon products, IC packaging materials, etc.

Characteristics

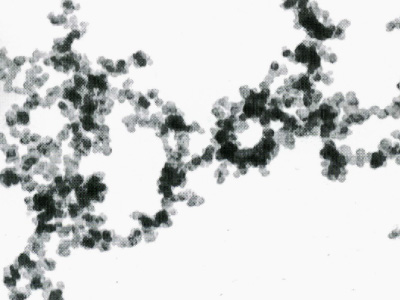

Although "DENKA BLACK" is essentially the same as other carbon blacks in that it consists of colloidal fine particles of carbon, it is considerably different in that its particles are linked in the form of a chain, and that its graphitization is very advanced. It therefore offers unique characteristics such as conductivity (electrical and thermal) and liquid absorption, among others.

Uses

Base material for dry cells, rubber reinforcements, cables, tires, belts, hoses, flooring, shoes, surface heating element, black pigment, electronic components, etc.

Related Information

(1) Unlimitedly High-purity Carbon -----

High Conductivity (Electric Conductivity, Thermal Conductivity, etc.)

"DENKA BLACK" is produced through self-heating pyrolysis of acetylene gas, which requires no oxygen for reaction. Therefore, it is highly pure, the amount of hydrogen existing therein as undecomposed residual matter or as a functional group is extremely small, and functional groups containing oxygen are not found. This closely relates to the fact that "DENKA BLACK" has excellent conductivity.

(2) High "Structure" ----- High Liquid-absorption and High Conductivity

Magnified through electron microscopy, "DENKA BLACK" appears in the shape of black balls linked together. This type of particle linkage is called the carbon black chain "Structure," and this "Structure" is highly developed in the case of "DENKA BLACK" compared with other carbon blacks. The apparent density of "DENKA BLACK" powder is low and this makes possible the retention of a large amount of liquid within this space. Also, besides particles being linked to one another, graphitization is well developed. This makes "DENKA BLACK" highly electrically and thermally conductive.

Applications of "DENKA BLACK"

Since its production was started in 1942, "DENKA BLACK" has played an important role as a rubber reinforcing

agent. From around 1948, acetylene black began to be used in dry batteries, and by 1950, acetylene black was

widely used as an alternative to natural black graphite. Accordingly, the application of "DENKA BLACK" was also

rapidly shifted from its use as a rubber reinforcing agent to use in dry batteries.

Recently, by taking advantage of its excellent high purity and electric/thermal conductivity, "DENKA BLACK", led

by the granule product category, is being widely used for semiconducting layer materials for extra high-voltage

cables, keyboards, rolls, belts and other conductive rubber, AV tapes, IC packing, and IC trays. In addition,

application of "DENKA BLACK" has been newly developed for various primary and secondary batteries, and further

applications in various areas are possible.

Dry Batteries

As for the reinforceability of "DENKA BLACK", it has such characteristics as (1) high hardness, (2) large heat generation properties, (3) high elasticity, and other average characteristics overall. Therefore, "DENKA BLACK" is used for printing rollers. In addition to reinforcement capability, "DENKA BLACK" has good heat dispersion and cut resistance, which is very suitable for tire bladders and racing tires exposed to severe use conditions and intense heat generation.

Rubber Reinforcing Agents

As for the reinforceability of "DENKA BLACK", it has such characteristics as (1) high hardness, (2) large heat generation properties, (3) high elasticity, and other average characteristics overall. Therefore, "DENKA BLACK" is used for printing rollers. In addition to reinforcement capability, "DENKA BLACK" has good heat dispersion and cut resistance, which is very suitable for tire bladders and racing tires exposed to severe use conditions and intense heat generation.

Conductive Material Mixing Agents

Among carbon blacks, the acetylene black "DENKA BLACK" in particular gives high conductivity. Compared with metal powder, "DENKA BLACK" has the following excellent properties:

- Improved product deterioration resistance due to the extremely pure carbon.

- Excellent product mechanical characteristics due to the reinforce capability of carbon black.

- Always available in a stable condition as acetylene black.

- Good processing characteristics.

- Extremely low level of carbon grit and other impurities due to its high purity.

Because of the above properties, "DENKA BLACK" has been used for semiconducting layer materials for cables for a long period of time.

Application of Conductive Materials

Cables

Conductive rubber is used on the semiconducting layer between a conductor and an insulator. Also, "DENKA BLACK" is very suitable for noise insulation material for communications cables, etc.

Belts

"DENKA BLACK" is used in belts used in plants and mines because belts are required to be electrically conductive in order to prevent electrostatic accidents.

Hoses

ectric discharge and fire are prevented by eliminating potential differences caused by static electricity which is generated between a hose, fluid, and the ground when fluid flows through the hose.

Floor

"DENKA BLACK" prevents electrostatic discharge on operating room floors in hospitals.

Shoes

Electrostatic sparks which don't cause problems in our daily life become a serious problem at explosives factories and at hospitals. Conductive shoes are effective measures for preventing such problems.

Rollers

Rollers are electrically charged due to continuous contact/ separation of objects, which may cause explosions and a deterioration workability due to inhalation. Mixing "DENKA BLACK" into rubber rollers gives them conductivity, and makes it possible for them to be used copiers and printing machines.

Heaters

When conductive rubber or conductive plastics are charged with electricity, they heat up like nichrome wires. Compared with metal, the heating of "DENKA BLACK" is even, light, and has the characteristics of rubber and plastics with excellent flexibility, which makes molding and processing easy. De-icers for propellers, heaters, and various other applications are being developed.

Surface Heating Elements

By giving conductivity to rubber and plastics with "DENKA BLACK" and charging them with electricity, the whole surface becomes a heating element. Such elements are used for floor heating and various road heating devices.

Conductive Paints/Adhesives

"DENKA BLACK" is used for the processing of various conductive materials, and for painting and adhesion of products which require electric and thermal conductivity.

Materials for Electronic Part

Since "DENKA BLACK" uses acetylene gas as a raw material, it is a high purity carbon black, making it very good for electronic materials. As for the case of making silicon rubber conductive, "DENKA BLACK" shows good conductivity and fewer curing obstructions.

Others

When "DENKA BLACK" is mixed into lubricating oil agents, their strength is increased, and their heat stability during high-temperature use greatly improves. "DENKA BLACK" is also usable in the metal industry for processes that require pure carbon, and as an agent for applying high-purity carbon in experiments and research. In the carbon industry, conductivity adjustments are possible by mixing "DENKA BLACK" into various carbon materials.

More Information

DENKA BLACK (trade name of DENKA ACETYLENE BLACK) is a carbon black produced by continuous thermal decomposition

of acetylene gas. DENKA BLACK is composed of colloid sized particles of carbon black, and has such unique

properties as good electrical conductivity, high solution absorption capacity, good thermal conductivity, etc.,

because of the following characteristics.

Each particle of acetylene black

- is composed of larger crystallites

- forms a longer chain structure

- has fewer impurities than other carbon black products

Therefore, DENKA BLACK has been used as a basic material for producing dry cell batteries, as well as for an additive in antistatic and electrically conductive rubber or plastic materials which are used in various industrial fields, such as electric wires and cables, tires, belts, hoses, heaters, paints, adhesives and many electronics parts.

Grades of "DENKA BLACK"

"DENKA BLACK" is divided into three groups according to its form:

[Powder Products] [Press Products] and [Granule Products]

[Powder Products] are light powder, which is in the state of being manufactured at a furnace.

[Press Products] enhance powder density by pressing powder products, which substantially reduces dispersion

during work.

[Granule Products] are easy to handle as there is almost no dispersion during work due to their high powder

density

Generally speaking, the powder and press products are suitable for dry batteries which require high liquid-absorption, and granule products are suitable for mixing with high molecular materials which require conductivity.

List of Physical Properties

(The figures for the physical properties of the products are not specifications but typical values.)

Special Conductive Material Dept. Product List

Sample Request

- It is the customer’s responsibility to always test products before use and confirm their fitness for purpose and safety.

- Any product contained on this Website or any product using a product contained on this Website should be disposed of in accordance with laws and regulations.

- Before use, please confirm the detailed method of use, precautions, and other information by using the technical documentation and Material Safety Data Sheet. These materials are available from the relevant Division. Please request them.

- The information contained in this website is subject to change without notice as new knowledge becomes available.